Battery recycling

From the beginning of the millennium, we have been witnessing a continuous technological progress that enhanced mobility and facilitated the transition from wired to mobile products, such as Etools, laptops and cellphones. It has also contributed to the development of urban transportation, such as electric bikes and scooters, electric vehicles and hybrids.

Though the increase in the use of these products has significantly improved our quality of life, it has also created new environmental challenges arising from the sharp increase in the amount of rechargeable battery waste. Battery life depends on a number of parameters, including battery type, its power, the way it’s used, etc. In most cases, a battery’s life span ends within a few years until it becomes waste.

Batteries contain toxic substances that pollute the environment. When a battery starts to decay, it releases a variety of substances that emit toxic greenhouse gases into the air. An old, unused battery in our living area will adversely affect our quality of life if handled incorrectly. For example, if a battery is thrown into a regular waste bin, it is highly likely that it will be buried in a landfill, which, in turn, will pollute the groundwater that we will drink in the future, as well as kill living creatures in the water and general ecosystem. That is why it is important to properly manage the battery disposal process.

Recycling batteries and their proper treatment is one of the most important issues in the field of recycling.

We at All Recycling operate according to the strictest industry procedures.

Following are the types of batteries commonly found in electronics today:

All Recycling operates in accordance with the electronic waste recycling law; it collects, sorts, packs and handles all the types of batteries mentioned above.

As for the Li-ion batteries, the company took sustainability one step further and developed a new and unique patent for their recycling. These batteries constitute and will continue to constitute the largest share of the battery market, due to an increase in demand for applications in the transportation sector (cars, bicycles and scooters). This share also defines the size of waste these batteries are expected to produce. If Li-ion batteries are not treated properly, they pose a great danger to the environment; they are highly flammable and may also cause damage to the groundwater by emitting cobalt, lithium, manganese and nickel into their surroundings.

Proper recycling means environmental protection and process safety; it also constitutes a kind of an “urban mine” for rare and sought-after metals.

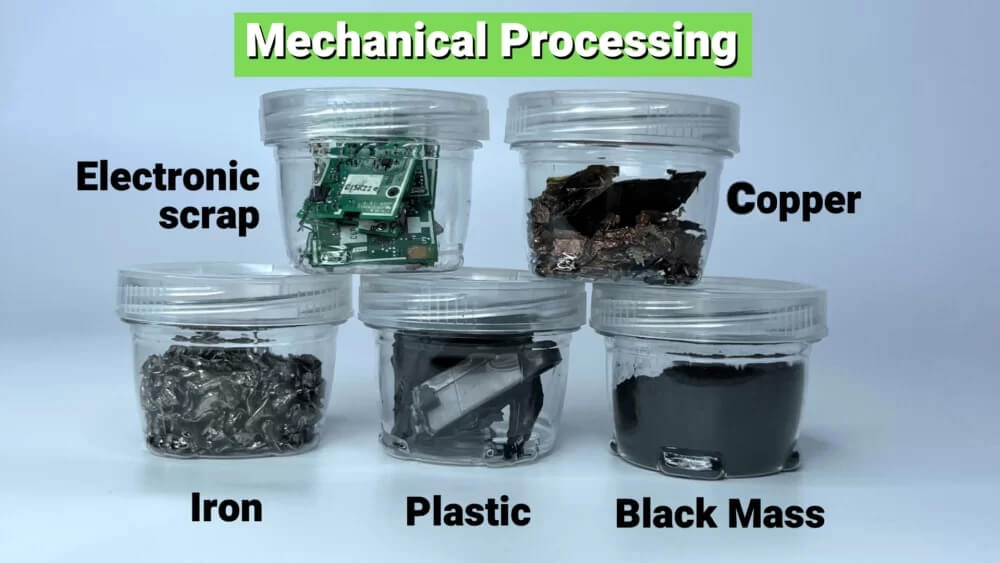

All Recycling developed a unique patent for the method of recycling of Li-ion batteries, which involves discharging the battery and extracting the metals it contains.

All Recycling is the leading and most advanced recycling company, in the Middle East and in Israel, for recycling electrical and electronic waste.

Advanced technologies, an innovative and advanced production line, experts with extensive and proven experience, nationwide coverage, and comprehensive management of our internal logistic unit enable us to help our customers implement recycling of electronic waste effectively, safely and in accordance with all environmental regulations. The attention to details and responsibility of all our staff provide our customers with peace of mind.

Our production line is one of the most advanced in the world, aimed at achieving 0% landfill and with no pollution whatsoever.

More Close

Strict management, registration and monitoring of all stages of the process, and issuance of certificates in accordance with the law and regulations.

More Close

All Recycling is a long-standing company, serving more than 1,000 of the largest concerns in the Israeli market.

More Close

The factory was built according to WEEE regulations and holds certificates for IS0-9001, ISO-14001, and Business Licenses from local authorities and the Office of Environmental Protection, as well as Toxin Handling Permits.

More Close

Strict recycling processes ensure complete destruction of devices and your data.

More Close

We allocate everything we treat to reuse whenever possible, and when that is not possible, send all recycled materials to be used as raw materials for industry.

More Close

Donating and empowering people with disabilities Also, food donations, volunteer work and more.

More Close

Reduce risk significantly by choosing a company that can provide you with All Recycling in your choice.

And the electronics of your organization or business IT is a broad and comprehensive solution in the entire field of equipment handling